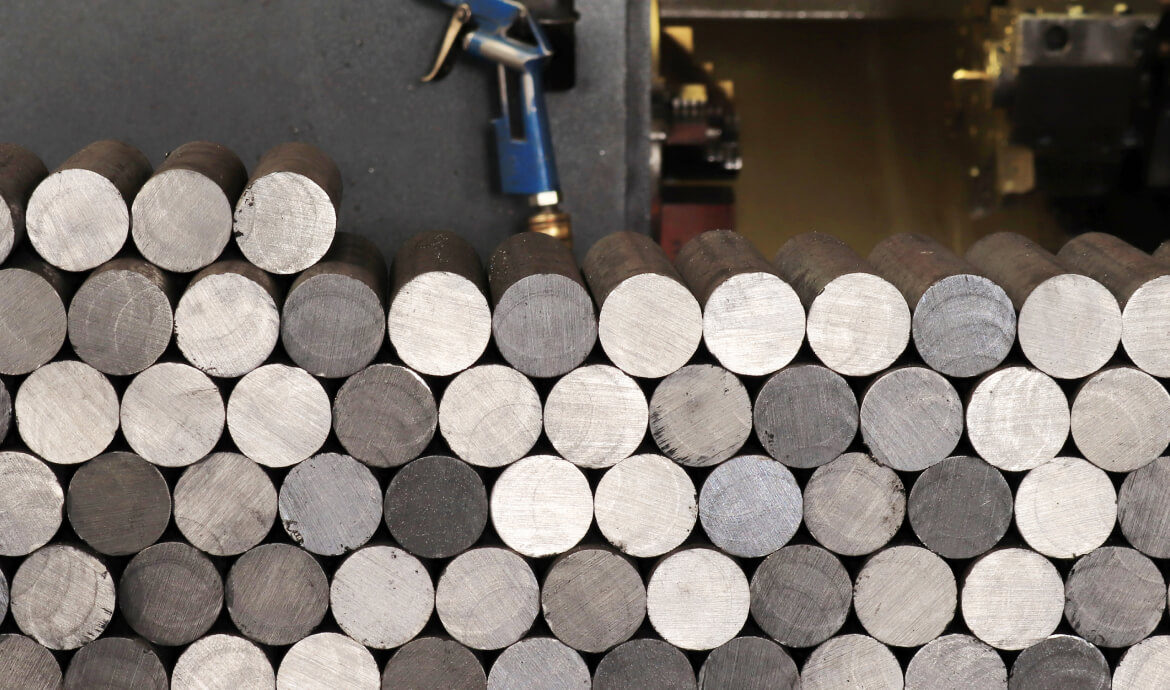

We have been processing steel for over 25 years

01. Control

02. Managment

03. Protect

04. Innovation

05. Strategy

Security of supply

Our in-house team of scientists is constantly fine-tuning the adopted methods and processes and guarantees that only top-quality powder is obtained. In the case of tungsten in particular.

Careful use of natural resources

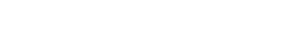

The input material for the recovery process consists of sintered hard tungsten carbide scrap, as well as soft scrap such as powders. Whether in electronics, coating technology, or high-temperature furnaces, where regular metals reach their limits, the refractory metals, alloys.

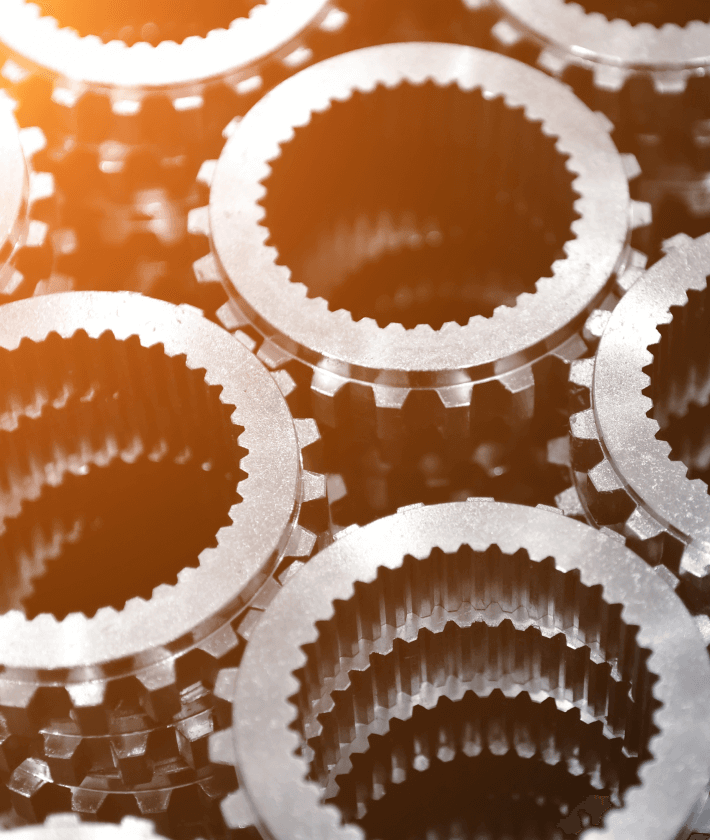

Aluminum vs. Steel. Benefits of Both

Powder coating is a popular industrial finish that can be used to coat a variety of materials, including metals, plastics, and ceramics. Powder coating typically works by applying the dry powder onto an item using an electric charge. This charge keeps the powder coat as tight as possible to the exterior.

The powder itself will contain resin and pigments for coloring, as well as other potential additives that help to reach the desired levels of thickness, hardness or shine. The process used to make the powder coating stick to the surface starts by pushing the powder through a spray gun with compressed air.

WHEN IS IT USED?

The added resistance to rust and corrosion that is provided by powder coatings allow the surfaces of steel beams, appliances, outdoor furniture, and similarly exposed material to stay clean and protected for much longer. There is a wide range of reasons as to why using powder coating may be the right option for the material you are looking to cover.

Because the coating is sealed onto the substrate with its electrostatic charge, the coating is held much tighter to the substrate.

The industrial processes move towards automation

Heat resistance, low thermal expansion, high thermal conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending.

When recently asked for him advice on making good career choices he said, “When you think about where you want to go to work, you should really think about what you want to do, not what seems fashionable or prestigious at the moment. It’s important, right from the start of your career, to do what you enjoy. It should be fun.

Security of supply

Our in-house team of scientists is constantly fine-tuning the adopted methods and processes and guarantees that only top-quality powder is obtained. In the case of tungsten in particular.

Careful use of natural resources

The input material for the recovery process consists of sintered hard tungsten carbide scrap, as well as soft scrap such as powders. Whether in electronics, coating technology, or high-temperature furnaces, where regular metals reach their limits, the refractory metals, alloys.

Our Industry Competence

The input material for the recovery process consists of sintered hard tungsten carbide scrap, as well as soft scrap such as powders.

We procure raw materials from unobjectionable sources

our components are used in worldwide industrials

Years of Experience

Skilled Professionals

Visited Conferences

Projects Worldwide

Stay informed on our latest news

our goals in numbers

Heat resistance, low thermal expansion, high thermal conductivity, good electrical conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending on the requirements.

Heat resistance, low thermal expansion, high thermal conductivity, good electrical conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending on the requirements.

Heat resistance, low thermal expansion, high thermal conductivity, good electrical conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending on the requirements.

Heat resistance, low thermal expansion, high thermal conductivity, good electrical conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending on the requirements.

Heat resistance, low thermal expansion, high thermal conductivity, good electrical conductivity, good corrosion resistance and wear resistance, high density, radiation absorption, outstanding purity – these are the decisive properties that we perfect depending on the requirements.